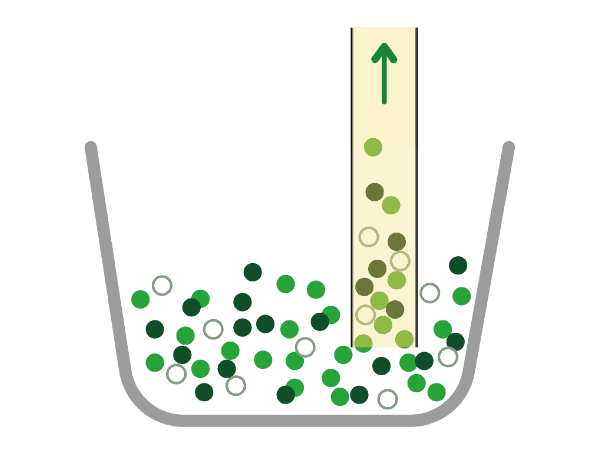

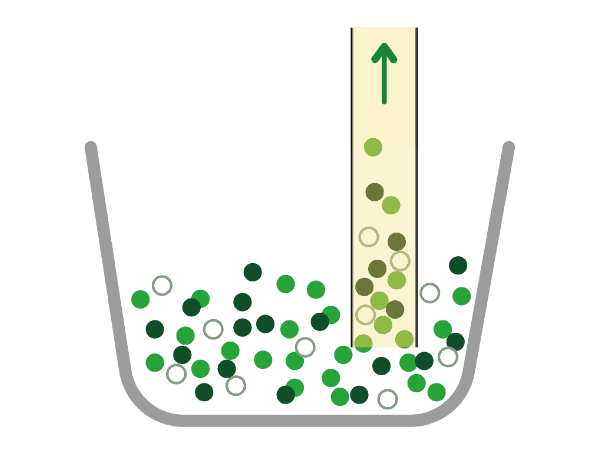

Mix the color masterbatch in a certain proportion and pump the color masterbatch to the extruder.

Stringent artificial grass production flow is the basis for producing high quality artificial grass. From raw material processing to final mechanical rolling, LRGrass always carries out production in strict accordance with relevant standards to ensure that we can provide best artificial grass for our customers.

Mix the color masterbatch in a certain proportion and pump the color masterbatch to the extruder.

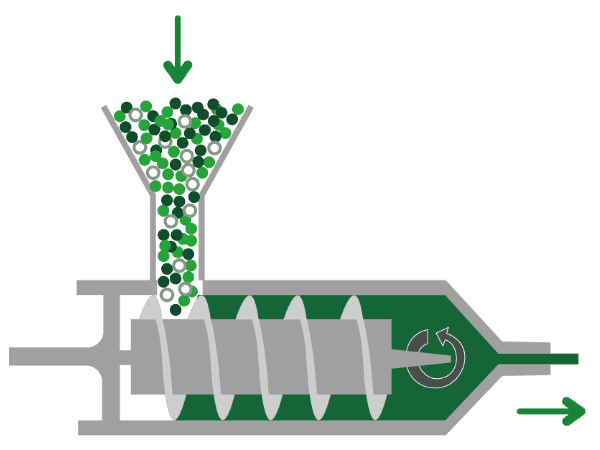

Extrude the color masterbatch into grass fibers and finalize the shape. Multiple times of extrusion may be required according to your needs.

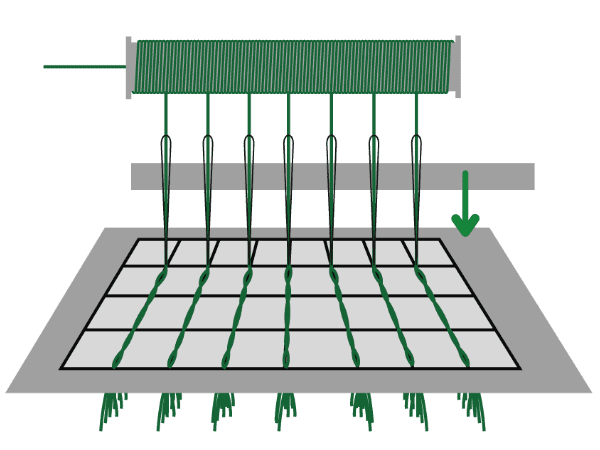

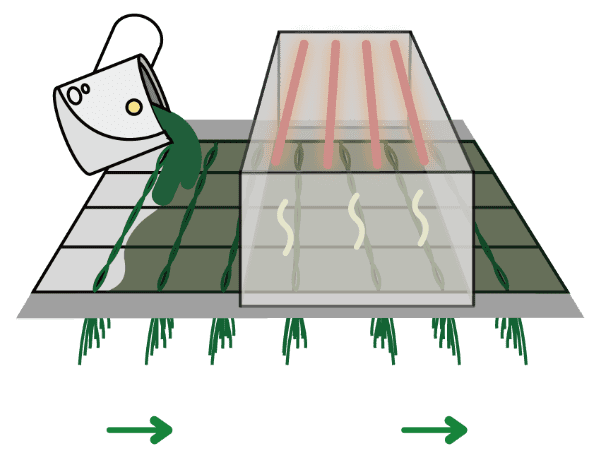

Tufting production process is used to tuft grass fibers from the bottom of the backing. And then perform manual inspection and replenish grass fibers.

Apply the glue on the backing of artificial grass, flat and dry the glue to make the adhesion between grass fibers and backing firmer.

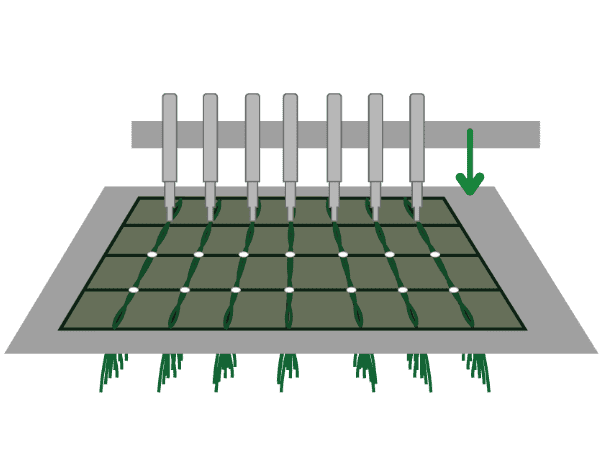

Equally spaced heat melt drainage holes enable the artificial grass to have good drainage effect during use.

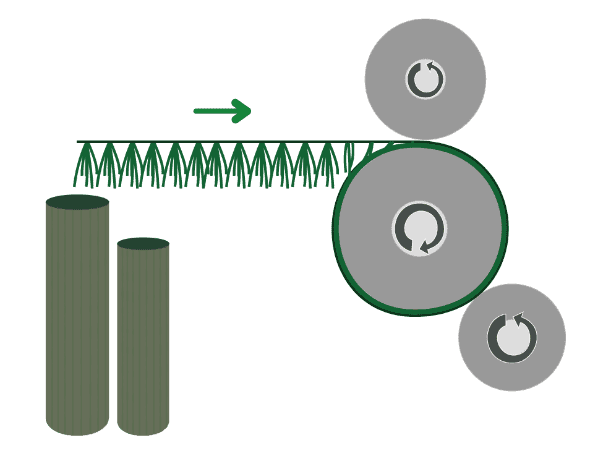

When the hole punching is completed, carry out final inspection and then roll up the artificial grass if everything is OK.