Artificial grass production process is a key link in artificial grass production. It not only affects the firmness of grass fiber and the adhesion of coating, but also concerns the lifespan of artificial grass.

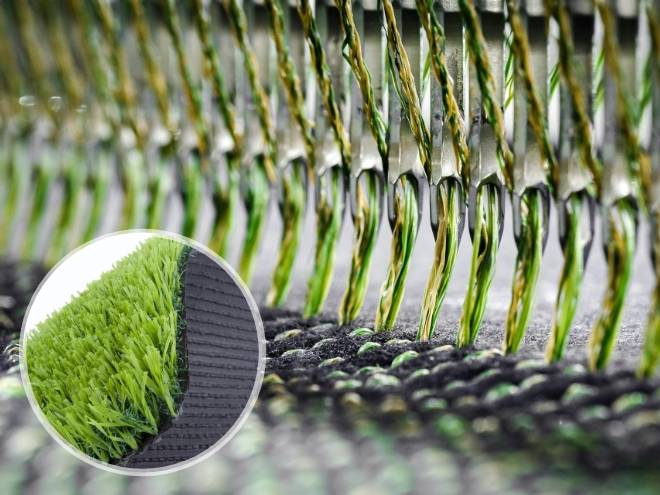

Tufting is the most common artificial grass production process. The principle of tufting machine is similar to a sewing machine. It tufts grass fibers into the backing through tufting needles, forming a U-shape tuft and making grass fiber arrangement uniform.

Needle moving mode. It either moves laterally or along z-direction. When needles move along z-direction, it makes grass fibers distributed evenly and offers high grass fiber coating adhesion.

Weaving artificial grass surface is a process that weaves the backing and grass fibers together to form a dense artificial grass surface. This artificial grass surface is highly stable and grass fibers has no fixed direction.

Multi-layer fibers are needled together to form grass fibers. Compared with other artificial grass, needle punched artificial grass surface offers highest porosity (If the material has high porosity, it indicates the material is not compact.), good wear-resistance and least sand content. So, it also requires a lower maintenance cost.